Discover how configurable, modular conveyor designs reduce installation time, lower costs, and provide unmatched flexibility for automation integrators and manufacturing operations.

The Integration Challenge in Modern Manufacturing

Adding conveyors to an existing production line shouldn’t mean shutting everything down for weeks. But with traditional systems, that’s often exactly what happens. Custom engineering drags on, fabrication takes forever, and every hour of downtime hits the bottom line.

Modular conveyors take a different approach. Standardized, pre-engineered components bolt directly into your current setup, cutting installation time dramatically. For automation integrators building new cells or plant engineers upgrading legacy equipment, it’s a way to get capacity online faster without ripping everything out and starting over.

What Are Modular Conveyors and How Do They Simplify Integration?

Modular conveyors are precision-engineered material handling systems built from standardized, interchangeable components that can be quickly assembled, reconfigured, and connected to existing production equipment. Unlike custom-fabricated conveyor systems that require extensive lead times and specialized installation, modular designs use universal mounting points, industry-standard pallet sizes, and plug-and-play control interfaces.

The key benefits of modular conveyor integration include:

- Reduced installation time: Pre-engineered sub-assemblies ship ready for fast installation, with many systems operational within days rather than weeks.

- Lower integration costs: Standardized components eliminate expensive custom fabrication and reduce engineering hours.

- Future-proof flexibility: Reconfigure layouts as production needs change without replacing entire conveyor runs.

- Seamless machinery connection: Universal T-slots, precision mounting points, and compatible control systems connect directly to existing equipment.

- Minimal production disruption: Modular components can be staged and pre-assembled off-line, minimizing costly downtime during installation.

Common Integration Challenges Modular Conveyors Solve

Automation integrators and manufacturing engineers frequently encounter obstacles when connecting conveyors to existing production equipment. Understanding these pain points reveals why modular designs have become the preferred solution for modern integration projects.

Space Constraints and Layout Limitations

Production floors rarely offer ideal conditions for conveyor installation. Existing machinery, support columns, utility runs, and traffic patterns create complex obstacles. Traditional conveyor systems often require extensive custom engineering to navigate these constraints, adding weeks to project timelines and significant cost overruns.

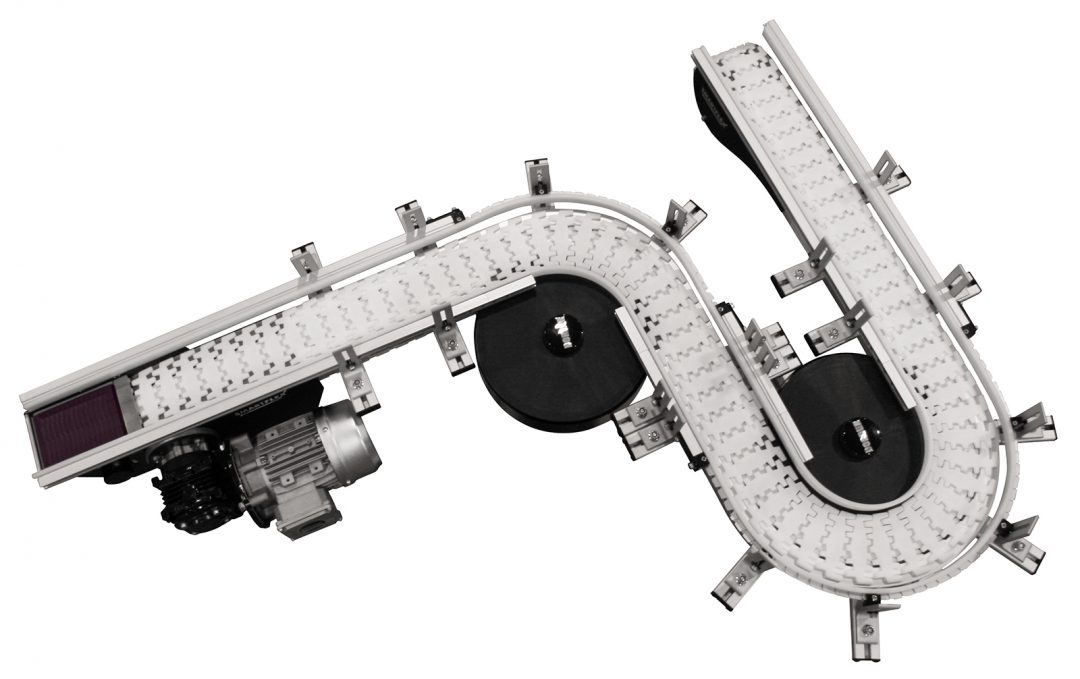

Modular flexible chain conveyors, like the Dorner FlexMove platform, address this challenge directly. With the industry’s most flexible plastic chain belt technology, these systems navigate tight turns, inclines, and declines in a single continuous run. Low-profile frame designs fit into spaces where conventional conveyors cannot operate, enabling integration in the most challenging facility layouts.

Connecting to Diverse Equipment Types

Modern production environments often include equipment from multiple vendors, each with different mounting standards, control protocols, and timing requirements. This equipment diversity creates significant integration complexity.

Modular conveyors solve this through standardized interfaces:

- Universal T-slots built into conveyor frames allow quick attachment of guide rails, sensors, and mounting brackets at any point along the length of the conveyor.

- Industry-compatible pallet sizes in pallet conveyor systems ensure smooth product handoffs between different manufacturers’ equipment.

- Control solutions integrate with multiple PLC platforms, including Allen-Bradley, Siemens, and Keyence, using standard protocols like Ethernet/IP and IO-Link.

Meeting Precision Positioning Requirements

Automated assembly, robotic pick-and-place operations, and vision inspection systems demand precise product positioning—often within fractions of a millimeter. Achieving this accuracy while integrating with existing machinery requires conveyors specifically designed for precision applications.

The DualMove Pallet System addresses this need with timing belt-driven technology that achieves positioning accuracy within ±0.5mm. Precision Move conveyors in the 2200 and 3200 Series offer mechanical accuracy of ±0.02″ with servo motor index repeatability of ±0.04″, enabling seamless integration with high-precision automation equipment.

Key Advantages of Configurable Modular Designs

Standardized Components for Faster Assembly

The foundation of simplified integration lies in standardization. When conveyor components follow consistent design standards, integration becomes predictable and repeatable. Rather than engineering each connection point from scratch, integrators select from proven component libraries that include pre-engineered curves, inclines, merges, and transfer modules.

Dorner’s modular conveyor platforms demonstrate this principle. Dorner’s low-profile, aluminum frame conveyors feature a single-piece frame design with universal T-slots that accept industry-standard hardware. This eliminates custom bracket fabrication and allows accessories like photo-eyes, sensors, and product guides to mount in minutes rather than hours.

Every conveyor series also features a range of transfer tail options, from nose bar rollers for small parts transfers to powered rollers for unstable or heavy products. Matching transfer points to the needs of a production line ensures seamless product transport, positioning accuracy, and reduced product damage from misalignment or toppling.

Reconfigurable Layouts for Evolving Production Needs

Production requirements change. New products launch, volumes fluctuate, and processes evolve. Traditional conveyor systems become stranded assets when layouts need modification—expensive to remove and difficult to reconfigure for new production requirements.

Modular conveyors with customizable zoning capabilities transform this equation. Pallet conveyors such as Dorner’s ERT series and DualMove series offer in-the-field customizability for production zones, allowing for pallet accumulation and redirection based on fluctuating production line needs. The cross-compatible design of these systems also simplifies expanding or reconfiguring the line layout to create new work zones for different processes or increased volume requirements.

Plug-and-Play Control Integration

Control system integration often represents the most complex aspect of connecting new conveyors to existing machinery. Different equipment uses different communication protocols, safety circuits, and programming languages. Without careful planning, control integration can consume more time and budget than the mechanical installation.

Dorner’s Controls Solutions, powered by Magnetek, address this challenge with UL508A-certified control systems designed for seamless integration. These systems support standard machine communication protocols including Ethernet/IP and IO-Link, with compatibility across major PLC platforms. The turnkey approach shifts control integration burden from the customer’s engineering team to experienced specialists, accelerating project timelines and reducing technical risk.

Modular Conveyor Solutions for Integration Applications

Different integration scenarios require different conveyor capabilities. Understanding which modular platform fits specific application requirements ensures successful integration outcomes.

FlexMove Flexible Chain Conveyors

When integration requires navigating complex layouts with tight turns, elevation changes, and space constraints, FlexMove flexible chain conveyors deliver exceptional versatility. The platform’s modular design supports widths from 45mm to 260mm, lengths up to 30 meters, and loads up to 600 lbs.

Key integration features include:

- Complete systems shipped as sub-assemblies for fast installation

- Accessory modules including dry cleaning, wet cleaning, popup stops, and side acting merges

- Both aluminum and stainless steel component options

- Easy integration with controls, photo-eyes, sensors, and automation equipment

- Helix, twist, wedge, and alpine configurations for vertical product movement

2200 and 3200 Series Fabric & Modular Belt Conveyors

For precision applications requiring accurate product handling and high-speed performance, the 2200 and 3200 Series belt conveyors provide proven integration solutions. The 2200 Series handles loads up to 150 lbs at speeds to 400 ft/min, while the heavy-duty 3200 Series manages loads up to 1,000 lbs at speeds to 600 ft/min.

Integration-friendly features include:

- Universal T-slots for quick accessory mounting

- V-guided belting for positive belt tracking

- Available in straight, curved, incline, decline, and Z-frame configurations

- High-speed nose bar transfer options for small part handling

- Precision Move variants with ±0.02″ positioning accuracy

Pallet System Conveyors

Automated assembly and testing applications often require precise product routing with accurate stop positioning. Pallet conveyor systems provide this capability through timing belt, flexible chain, and edge roller technology designs.

The DualMove Pallet System features twin timing belt-driven pallets with positioning accuracy within ±0.5mm—ideal for robotics integration and automated assembly operations. Edge Roller Technology (ERT) systems offer a belt-free, open-frame design verified* for Class 4 cleanroom applications in electronics, pharmaceutical, and medical device manufacturing.

Pallet system integration advantages include:

- Industry-compatible pallet sizes for equipment interoperability

- Pin tracking system for simple, cost-effective pallet routing

- Wide variety of modules for traffic management and flow control

- Customizable pallet sizes to match existing tooling

- Easy field reconfiguration as production requirements evolve

Modular Conveyor Platform Comparison for Integration

| Feature | FlexMove | Belted Conveyor Series | Pallet Systems |

| Best For | Complex layouts, tight spaces | Precision, high-speed handling | Assembly, robotics integration |

| Load Capacity | Up to 600 lbs | Up to 1,000 lbs (3200 series) | 16-800 lbs (varies by series) |

| Max Speed | 250 ft/min | 600 ft/min | Application-specific |

| Positioning Accuracy | Standard | ±0.02″ (Precision Move) | Up to ±0.5mm |

| Reconfigurability | Excellent | Good | Excellent |

| Cleanroom Compatibility | Not Verified for Cleanrooms | Class 100 (1100 Series) | ERT Class 4 |

Step-by-Step Integration Process

Successful conveyor integration follows a structured approach that minimizes risk and maximizes first-time success. Whether you’re an automation integrator designing for a client or a manufacturing engineer improving internal operations, this proven process ensures optimal outcomes.

- Application Assessment: Define product characteristics (size, weight, stability), throughput requirements, precision needs, and environmental conditions. Document existing equipment interfaces, including mounting points, control protocols, and timing requirements.

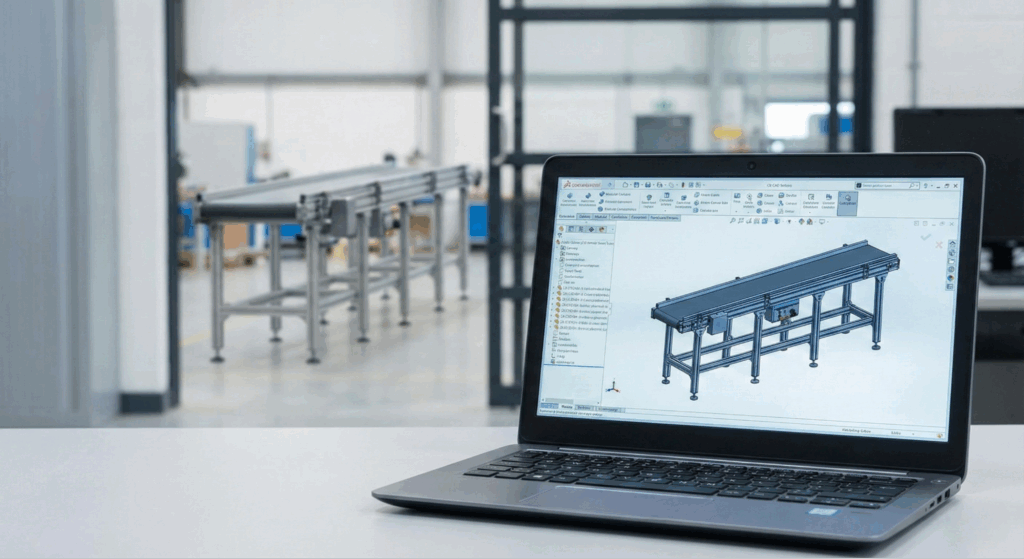

- Layout Design: Use DTools, Dorner’s industry-leading CAD/Configurator software, to design custom conveyor configurations. The platform enables quick iteration of layout options while ensuring component compatibility.

- Control Integration Planning: Identify control system requirements, including PLC platform, communication protocols, safety circuits, and I/O requirements. Determine whether standard control packages or custom controls solutions are appropriate.

- Component Selection and Order: Select appropriate conveyor platform, modules, and accessories. Most Dorner conveyors are built-to-order and ship in as little as 72 hours, with complete systems shipping as sub-assemblies for fast installation.

- Installation and Commissioning: Install mechanical components, connect controls, and commission the system. Dorner’s experienced service technicians provide on-site start-up support and training to ensure successful integration.

Frequently Asked Questions About Modular Conveyor Integration

How long does modular conveyor integration typically take?

Integration timelines vary based on project complexity, but modular designs significantly accelerate installation compared to custom-fabricated systems. Simple single-conveyor integrations may complete in one to two days, while complex multi-conveyor cells with integrated controls typically require one to two weeks. Most Dorner conveyors ship in five days or less after order, further compressing project schedules.

Can modular conveyors connect to equipment from different manufacturers?

Yes. Modular conveyor platforms use standardized interfaces specifically designed for multi-vendor environments. Universal T-slots accept industry-standard mounting hardware, control systems support multiple PLC platforms and communication protocols, and pallet systems use industry-compatible pallet sizes. This interoperability ensures smooth integration regardless of existing equipment brands.

What industries benefit most from modular conveyor integration?

Industries requiring flexibility, precision, and fast changeover benefit most from modular designs. This includes automation integrators serving multiple end markets, medical device and pharmaceutical manufacturers with cleanroom requirements, e-commerce and packaging operations with high product variety, and automotive and electronics manufacturers with complex assembly processes. Modular platforms adapt to these diverse requirements without custom engineering for each application.

How do modular conveyors reduce total cost of ownership?

Modular designs reduce total cost of ownership through multiple mechanisms: lower initial installation costs due to standardized components and faster assembly, reduced downtime during integration, ability to reconfigure rather than replace when production needs change, simplified maintenance with readily available replacement parts, and extended system life through component reuse. This comprehensive cost advantage often delivers payback within months rather than years.

What support is available during the integration process?

Dorner provides comprehensive integration support including application engineering consultation, DTools CAD/Configurator software for layout design, on-site start-up and commissioning services, operator and maintenance training, and lifetime technical support backed by an industry-leading 10-year warranty. For projects requiring integrated controls, the Controls Solutions team provides turnkey project management from discovery through field start-up.

Integration Readiness Assessment Checklist

Before beginning a modular conveyor integration project, evaluate these critical factors to ensure project success:

- Product Characteristics: Document product dimensions, weight range, stability, and special handling requirements (fragile, temperature-sensitive, etc.)

- Throughput Requirements: Define products per minute, cycle times, and accumulation needs

- Space Constraints: Measure available floor space, ceiling height, and clearance requirements around existing equipment

- Existing Equipment Interfaces: Document mounting points, infeed/outfeed heights, and handoff requirements

- Control System Architecture: Identify PLC platform, available I/O, communication protocols, and safety requirements

- Environmental Conditions: Note temperature, humidity, washdown requirements, and cleanroom classifications

- Future Flexibility Needs: Consider potential product changes, volume growth, and layout modifications

Measuring Integration ROI: Key Performance Indicators

Quantifying the value of modular conveyor integration helps justify investment and guides future decisions. Track these metrics to measure integration success:

- Installation Time Savings: Compare actual installation hours to estimates for custom-fabricated alternatives. Modular systems typically reduce installation time by 40-60%.

- Production Downtime Reduction: Measure production hours lost during integration. Pre-assembled modular components minimize on-site work and associated downtime.

- Throughput Improvement: Track products per hour before and after integration. Properly designed conveyor systems can increase throughput by up to 30%.

- Maintenance Cost Reduction: Compare maintenance hours and parts costs. Standardized components simplify troubleshooting and reduce spare parts inventory requirements.

- Reconfiguration Costs: When production changes require layout modifications, measure the cost and time required. Modular designs typically enable reconfiguration at 20-30% of replacement cost.

Get Started with Modular Conveyor Integration

Dorner’s application and support team brings decades of experience creating intelligent motion solutions for automation integrators and manufacturing operations across industries. With the broadest range of unit-handling conveyors available, we help you find the right modular solution for even the most challenging integration projects.

Ready to simplify your next integration project? Contact Dorner’s team for a consultation, request a quote for your specific application, or use DTools to start designing your custom conveyor configuration today.

With over 50 years of conveyor innovation, an industry-leading 10-year warranty, and the fastest lead times in the industry—most conveyors ship in 5 days or less—Dorner delivers modular conveyor solutions that simplify integration and keep your operations running

**To verify clean room requirements, an unloaded base conveyor was tested and did not generate particulate that would be beyond the specified standards. However, the verification does not provide assurance that any or all applications will meet this requirement. Application testing is recommended to ensure clean room standards are being met. Dorner takes no responsibility in the clean room performance of the final conveyor or application.