Drive Modules

Contact Us

Conveyor specialists are ready to help you find the right solution

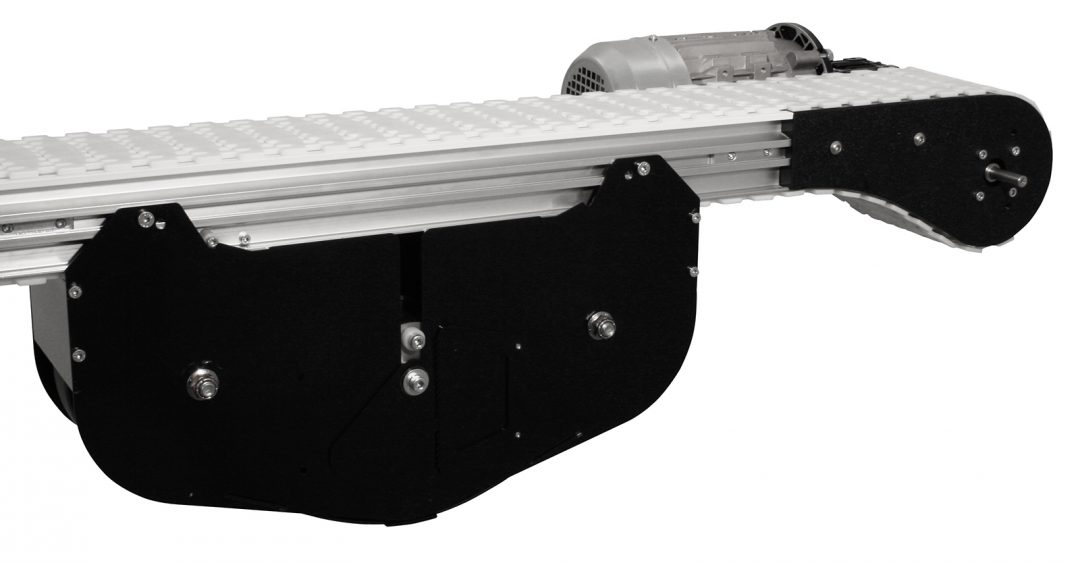

Direct Catenary Drive Module

- Lengths:

- Minimum = 481mm (1.58ft)

- Maximum = 25 m (95 ft)

- Minimum tail only (knuckle modules, and plain bend corner) = 329 mm (1.08 ft) (contact factory)

- Drive Sprocket:

- 65 mm = 16 tooth

- 105 mm and 150 mm = 12 tooth

- Pitch Diameter:

- 45 & 65 mm = 129 mm (5.093 in)

- 85, 180 & 260 mm = 128 mm (5.038 in)

- 105 mm and 150 mm = 136 mm (5.336 in)

- Maximum incline or decline = 7°

- 3/4” and 20 mm Drive Shafts available

- Uses catenary loop for belt take-up

- Side mount sealed gearmotors can be in position 1, 2 or 3

- Optional 20mm diameter x 1.5 in long dual output shaft for common driven conveyors

Direct Guided Profile Drive Module

- For use with gravity takeup or fully contained chain

- Lengths:

- Minimum = 481mm (1.58ft)

- Maximum = 25 m (95 ft)

- Minimum tail only (knuckle modules, and plain bend corner) = 329 mm (1.08 ft) (contact factory)

- Drive Sprocket:

- 65 mm = 16 tooth

- 105 mm and 150 mm = 12 tooth

- Pitch Diameter:

- 45 & 65 mm = 129 mm (5.093 in)

- 85, 180 & 260 mm = 128 mm (5.038 in)

- 105 mm and 150 mm = 136 mm (5.336 in)

Maximum incline or decline = 7°

- 3/4” and 20 mm Drive Shafts available

- Side mount sealed gearmotors can be in position 1, 2 or 3

- Optional 20mm diameter x 1.5 in long dual output shaft for common driven conveyors

- Optional power transfer available for small part in-line transfer applications

Suspended Drive

- Lengths:

- Minimum = 481mm (1.58ft)

- Maximum = 25 m (95 ft)

- Minimum tail only (knuckle modules, and plain bend corner) = 329 mm (1.08 ft) (contact factory)

- Drive Sprocket:

- 65 mm = 16 tooth

- 105 mm and 150 mm = 12 tooth

- Pitch Diameter:

- 45 & 65 mm = 129 mm (5.093 in)

- 85, 180 & 260 mm = 128 mm (5.038 in)

- 105 mm and 150 mm = 136 mm (5.336 in)

Maximum incline or decline = 7°

- 3/4” and 20 mm Drive Shafts available

- Uses catenary loop for belt take-up

- Optional 20mm diameter x 1.5 in long dual output shaft for common driven conveyors

Weighted Take-Up Module

- Provides compact tail for in machine applications

- Lengths:Minimum = 700 mm (27.56 in)

- Uses weighted idler roller and sight gauge for belt take-up

- Take-up module should be located within 2 m (78 in) of discharge end

Please see Engineering Manual for more information

Accessories

Belting

Support Stands

Gearmotors

Profiles & Guiding

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| FlexMove Engineering Manual | 244 | 55.2 MB |

| Literature | Pages | File Size |

| FlexMove Brochure | 8 | 2.9 MB |